Making Cut Tips

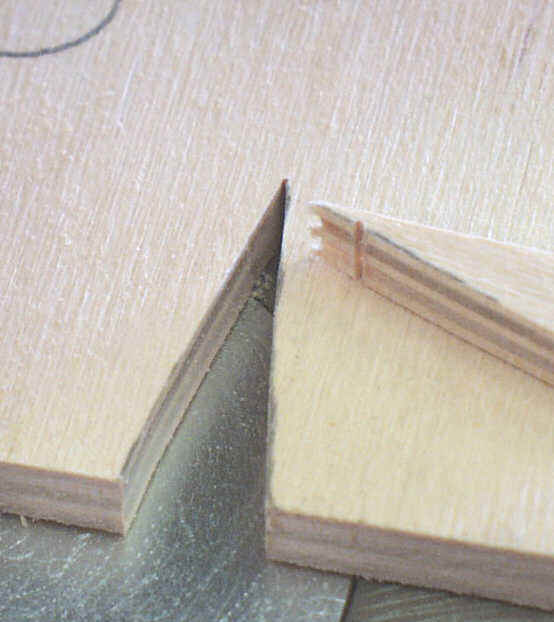

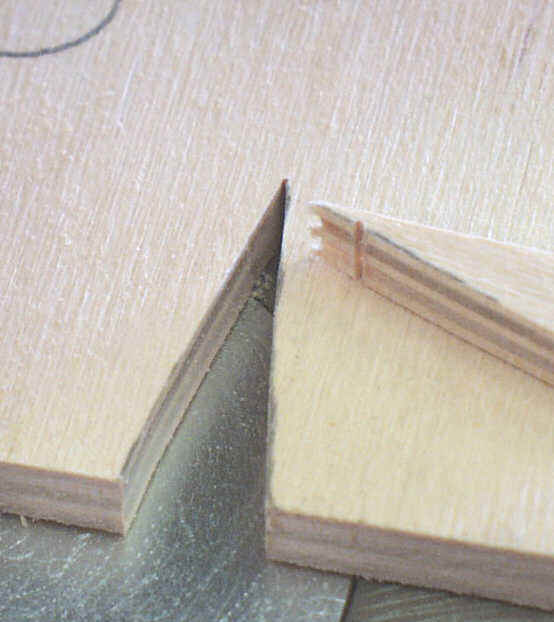

Here I have 5 layers of 1/8" Baltic Birch nailed together in a stack to cut out a leaf pattern.

Here I have 5 layers of 1/8" Baltic Birch nailed together in a stack to cut out a leaf pattern.

These are an item I will be cutting at a Business Expo for a give-away item for our Chamber of Commerce, the leaf is on our town signs, and the G signifies Grimes.

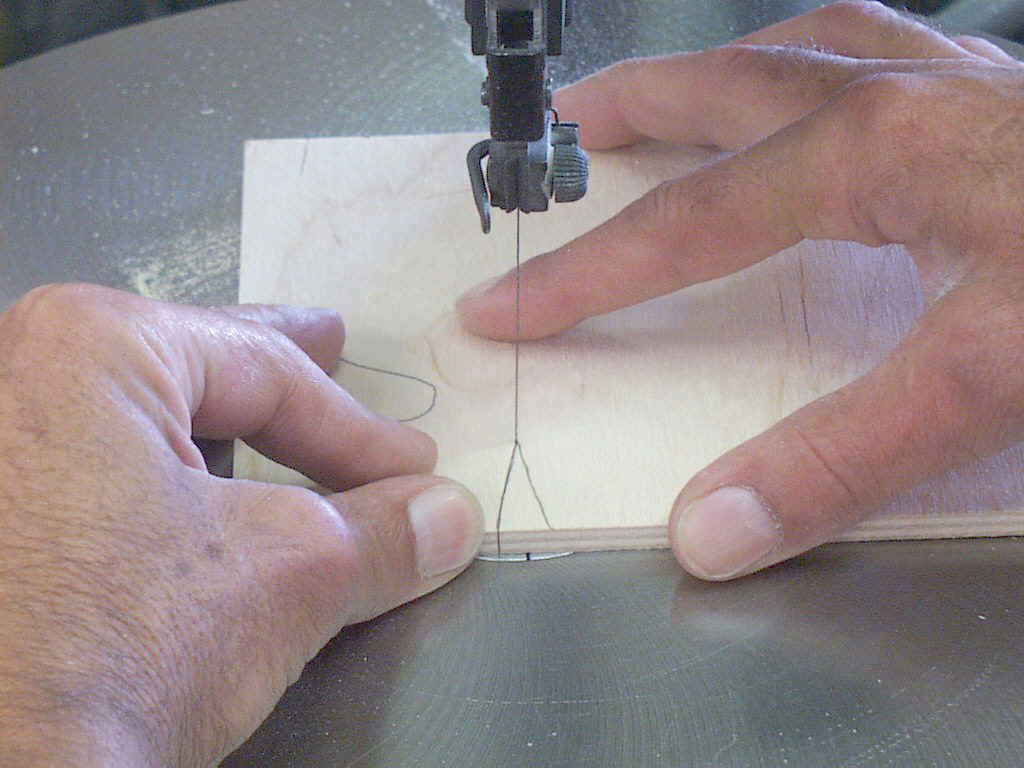

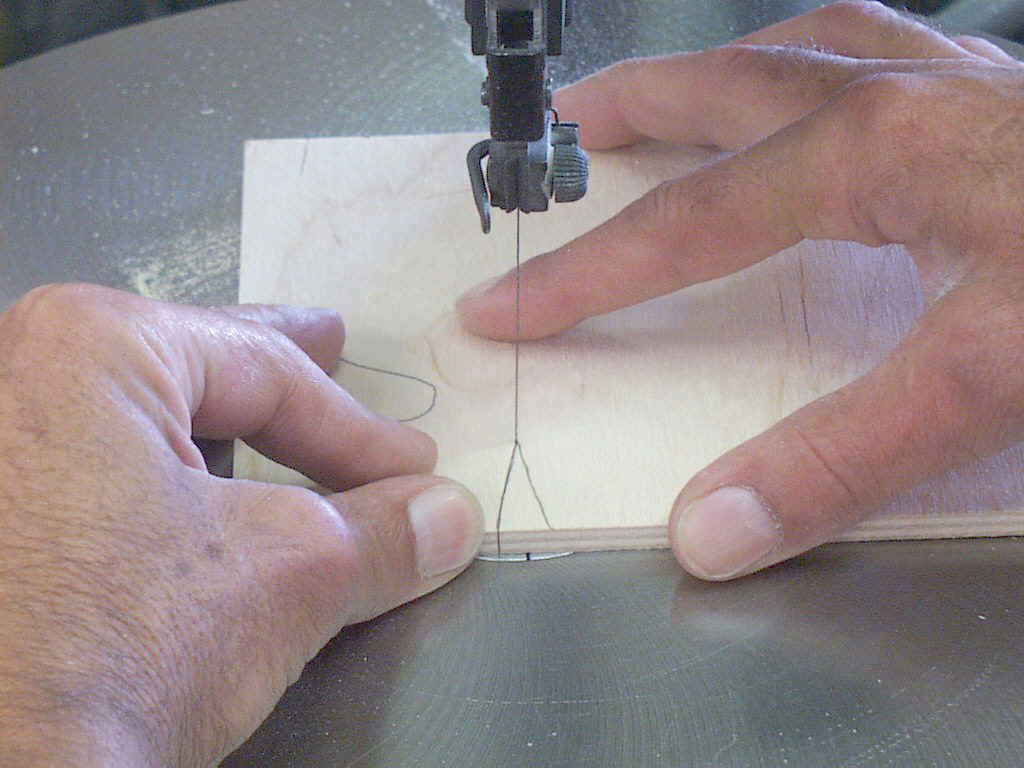

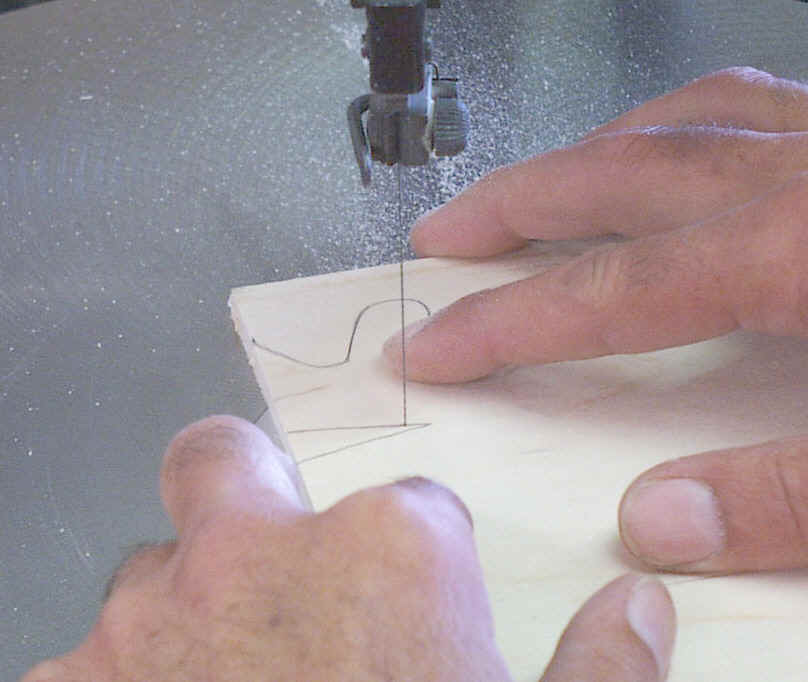

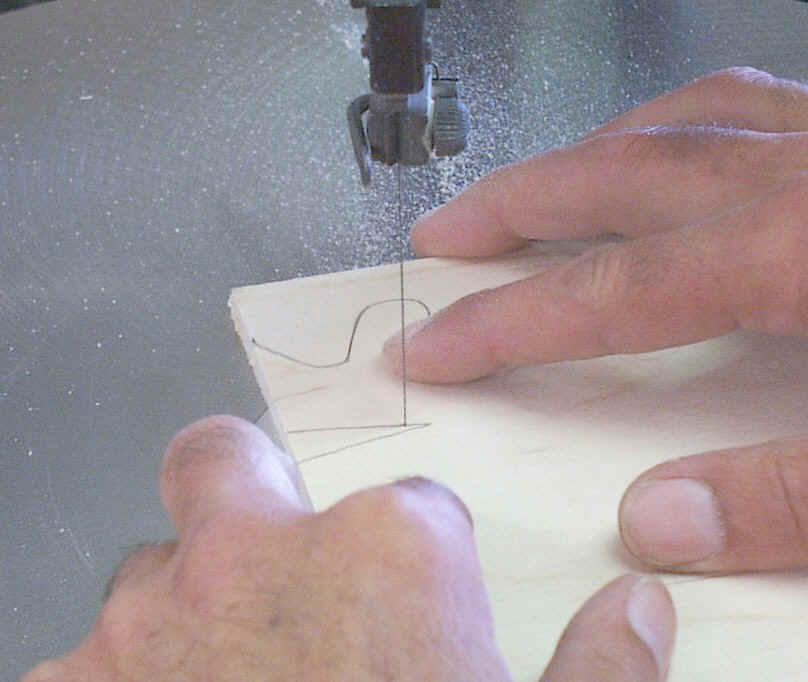

Notice how my fingers are positioned

close to the cutting to hold the work down and rotate it around for the cutting. The finger closest to the blade is used as a pivot for turns.

Notice how my fingers are positioned

close to the cutting to hold the work down and rotate it around for the cutting. The finger closest to the blade is used as a pivot for turns.

Also look at the way the computer generated a pattern with very little waste in cutting out the multiples of the leaf.

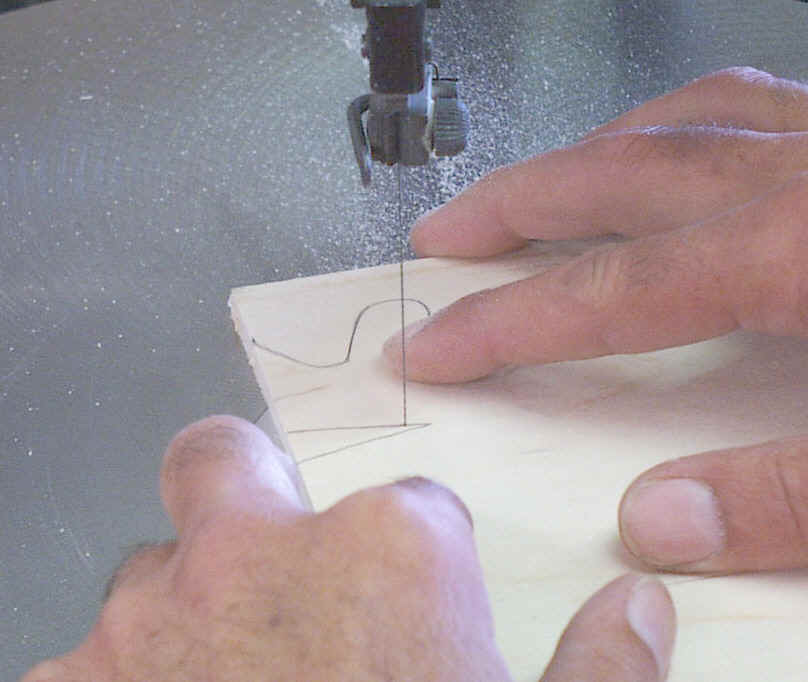

Notice how the fingers are positioned close to cutting,

this is to hold the work down.

Notice how the fingers are positioned close to cutting,

this is to hold the work down.

Then the thumbs are on the edges of the wood to feed the work into the blade for cutting.

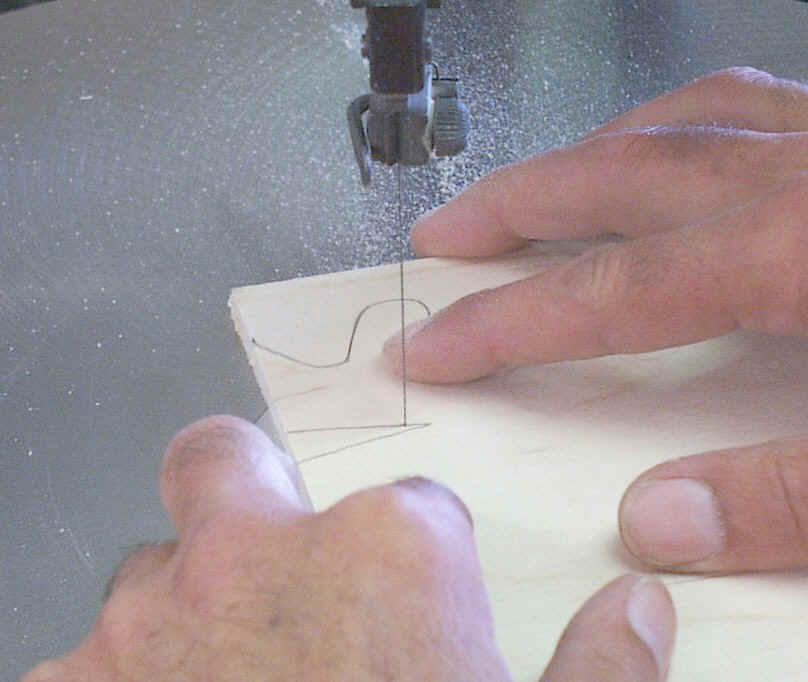

Here the left hand is using a nail as a handle to pivot the work. Once you start using those nails as a handle, you start putting more nails into the wood than you need just so you have one accessible.

Here the left hand is using a nail as a handle to pivot the work. Once you start using those nails as a handle, you start putting more nails into the wood than you need just so you have one accessible.

Cutting Basics:

We all know how to run that new scroll saw that we just

received. Take it out of the box and set it on the bench , turn it on and go.

Remember that the manual was made for the dumb people, we don't need it. Well in

away that is right, the manuals don't tell us how to actually cut on the saw.

They just tell us all about the saw.

So what did we learn form trying to just take off cutting? First thing we

found out is that the blades don't cut in line with the arm. They all seem to

cut off to the right. This is caused from the manufacturing process used on the

blade. If you very lightly run your finger up the left and right side of the

blade you will notice that the blade has a sharper edge on the right side, This

burr is like the tear out we see on the bottom of the wood that we just sawed.

But this burr also causes us a problem that it makes the right side of the blade

cut better. If you try this with the Precision Ground blades , there will not be

a burr. The PGT ( Precision Ground Tooth) blade is manufactured a different way

to eliminate the burr. But I'm not suggesting that you only buy PGT blades.

There are easier ways to cope with the burr problem.

Get back on the saw. Take a piece of wood and cut into it by feeding it

straight into the blade, aliened with the center of the top arm. Cut about Ĺ"

to ĺ" into the wood. Notice how the blade cut off to the right. Leave the

wood in place on the saw table.

The

white paper is in

line with the arm. As we feed the wood straight down the arm, notice how the cut

veers off to the right.

With a ruler lying on the line, we really see how far

off the blade is cutting.

Now lay a ruler along the cut line that the blade just made. Notice that it

points off to the left side of the rear of the saw. Move yourself around the saw

until you are looking straight down the ruler, you should be about 3" -

5" to the right of the center of the saw. Remember where you are at. Now

take that same piece of wood and again try cutting into it in a straight line,

by pushing it straight into the blade. Notice how much easier it is to follow

the line. From this position we can actually feed the wood straight at the blade

and it really follows the line. Isn't that neat.

Next look at how you are holding onto the wood. Most people have taken the

hold down off the saw, so that they have easier access and a better view of the

blade cutting area. That means you are going to have to apply some down pressure

to the wood. We are not saying white knuckle pressure, just some pressure. You

are also need to have a hold that allows you move the wood around the

blade. Remember with the scrollsaw you are feeding the wood at the blade, not

the blade at the wood. Place on hand on each side of the blade onto the wood.

I find the best way is to hook the tip of the thumb and one finger over the

edge of the wood, and use the rest of the fingers as the hold down fingers.

For making straight line cuts , both hands will feed the wood straight at the

blade. Since we are in line with the cutting path of the blade, we will end up

with a straight cut on that line.

Always keep your fingers off to the sides of the blade, so that if your

finger slides it does not slide into the blade. On some cuts where you are

trying to shave off a narrow strip , the blade could jump out of the cut

allowing the wood to jump forward. And if your finger was in that path it goes

forward right into the blade, not a good thing. This explains the holding of the

wood for straight line cuts, but for curves, there are some other factors.

For making smooth curves you will need to have a pivot point for your wood.

This pivot is made by using a finger tip. This is done by placing the finger tip

on the wood and applying enough pressure so that the wood will pivot around that

finger. Now you use the other hand to pivot the wood through the curve line you

are trying to cut. Depending on the direction of the curve will dictate which

hand it the pivot and which hand will be doing the turning. So when making

curves and turns, one hand will be stationary and the other hand will do the

turning. A little different than the method used for cutting straight lines.

Place the index fingertip from either hand on the wood and

applying enough pressure so that the wood will pivot around that finger. Use the

thumb and rest of the fingers of that hand to hold the wood down on the table.

You will then turn the wood with your other hand. The direction of the curve

will dictate which hand is the pivot and which hand is doing the turning. It is

easier to switch pivot hands to pivot the wood through the curves that flow in

the opposite direction.

I find it easier to cut curves if I pick an imaginary point

about 1/16" in front of the cutting path of the blade. The curve line being

cut should always be in line with that imaginary point. This seems to make it

easier for the blade to naturally follow the line.

Corners are generally created by using the following procedure: cutting to

one side; spinning the wood until the blade is in line with the new direction;

and feeding again. But, how do we hold that blade in place while the spin is

taking place?

The sides and back of the blade do not cut, so we can actually use them to

hold the bladeís position.

As you approach the corner, stop feeding the wood at the blade, and apply

slight pressure to the side of the blade at the outside of the corner, just to

help maintain the blade position. As you turn the wood to the new direction,

keep applying the pressure to the side, then back of the blade, until the new

direction line to be cut is aligned with the blade. It is easier to keep the blade in

the correct position for the new cutting direction location, by maintaining contact with

the sides or back of the blade on the wood

If this turn is not executed in a fast and smooth manner, without hesitation,

the sides and back of the blade will leave a burn mark. When I make these turns,

I spin the wood as fast as I can. The blade will follow or break, and 98% of the

time, it follows, making a nice corner.

Tight "Vís"

A slightly different approach is also used to scroll those tight

"V" type notches.

Cut down to the bottom of the "V," then back up a little into the kerf

you just cut. Using the side then back of the blade against the save piece (the

part of the project you are saving ), to maintain blade position , flip the wood

around 180 degrees , so the blade is now cutting in the opposite direction. The

teeth will have cut into the scrap part of the wood as you flipped the wood

around to reverse the direction of the blade.

Now, back the blade down into the end of the cut, at the bottom of the

"V". Turn the wood to the new direction, and cut out following the new

line. You should have just created a nice tight "V" that does not show

those tell-tale marks of cutting in from both directions.

Every time you start a cut and finish at the same place, there is a chance of

leaving a small nib of wood at that point, which will need to be sanded off later.

For those small nibs, try sanding them off with the burr on the right side of

the blade. You may need to slightly angle the blade as if you were trying to

just shave a little wood off the edge, but you will pick up this trick easily

after doing it a few times. It is amazing how easy it is to remove the nib this

way.

Using these methods for cutting, you should have a little better luck at

getting the blade to go where you wanted it to. Remember that for straight lines

both hands feed the wood at the blade. For curved lines one hand is the pivot

and the other hand will move the wood. And most importantly keep your fingers

out of the blade path.

Here I have 5 layers of 1/8" Baltic Birch nailed together in a stack to cut out a leaf pattern.

Here I have 5 layers of 1/8" Baltic Birch nailed together in a stack to cut out a leaf pattern.  Notice how my fingers are positioned

close to the cutting to hold the work down and rotate it around for the cutting. The finger closest to the blade is used as a pivot for turns.

Notice how my fingers are positioned

close to the cutting to hold the work down and rotate it around for the cutting. The finger closest to the blade is used as a pivot for turns. Notice how the fingers are positioned close to cutting,

this is to hold the work down.

Notice how the fingers are positioned close to cutting,

this is to hold the work down. Here the left hand is using a nail as a handle to pivot the work. Once you start using those nails as a handle, you start putting more nails into the wood than you need just so you have one accessible.

Here the left hand is using a nail as a handle to pivot the work. Once you start using those nails as a handle, you start putting more nails into the wood than you need just so you have one accessible.